For many years now, several awards and distinctions have rewarded our eco-innovation and R&D approach:

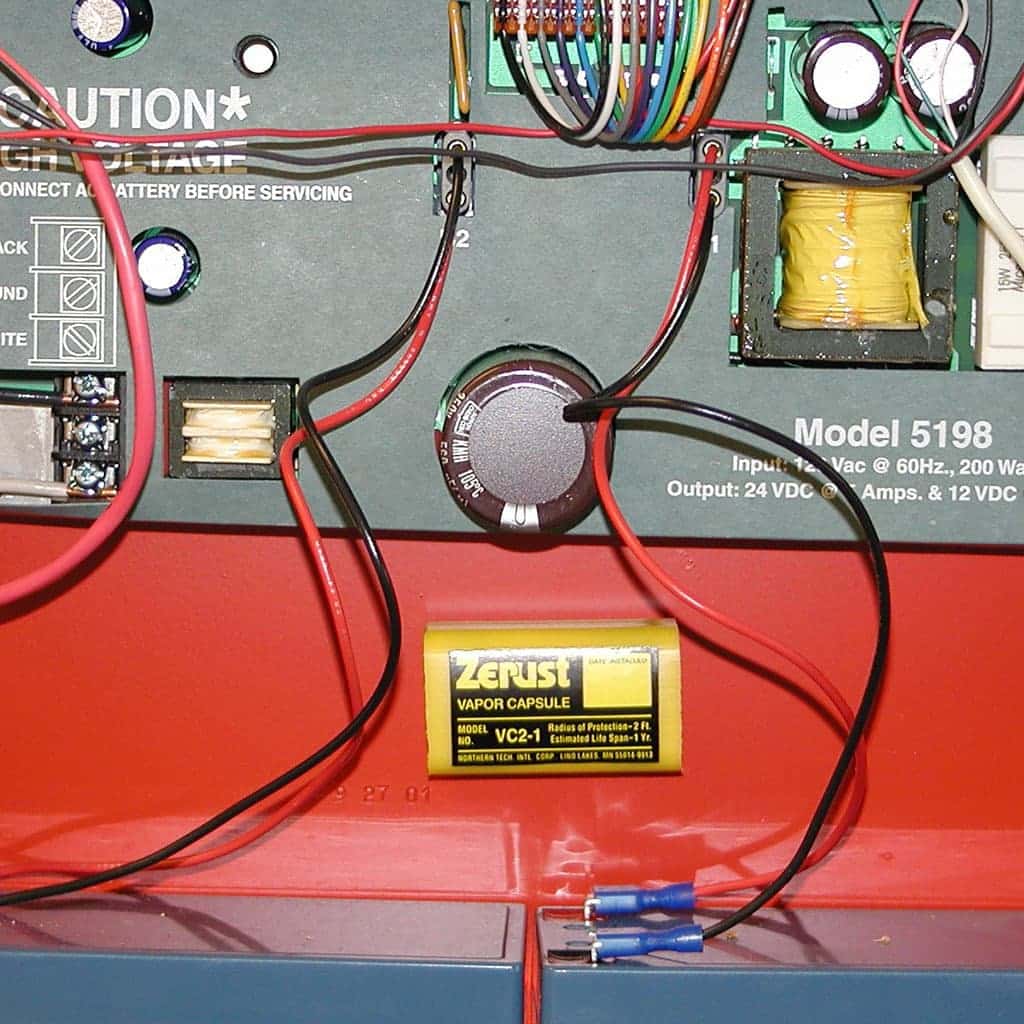

EVOLEN 2017 Innovation Award for the efficiency of our solutions in Oil&Gas.

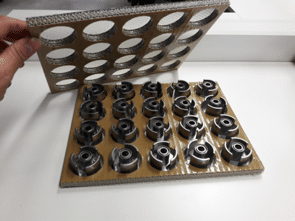

The PSA Supplier Award for the efficiency of our solutions in the automotive and transcontinental transport of equipment.

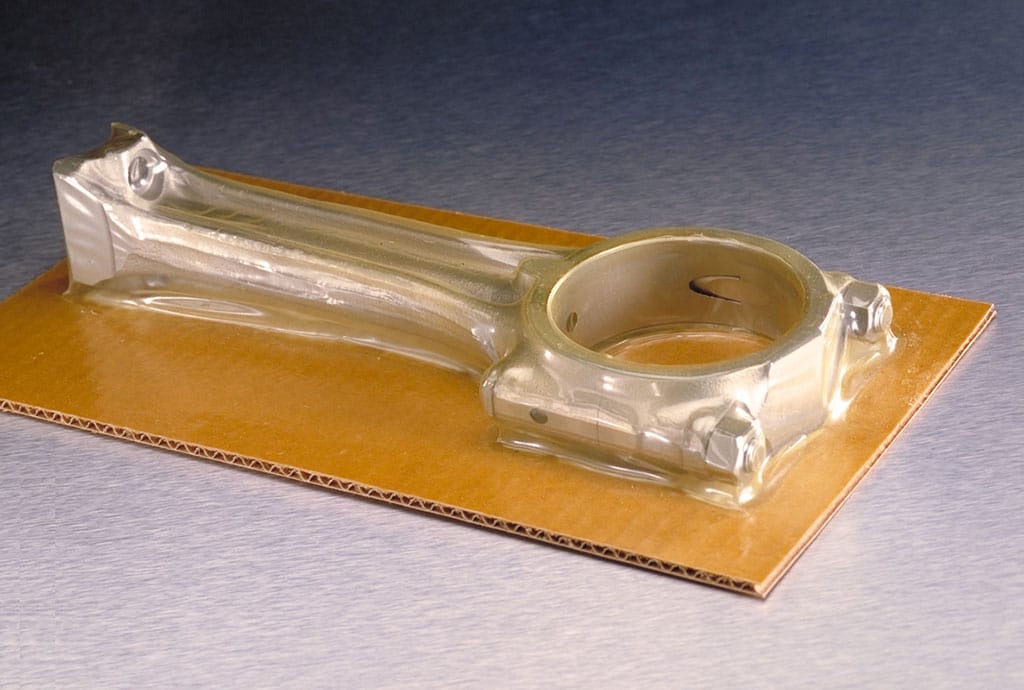

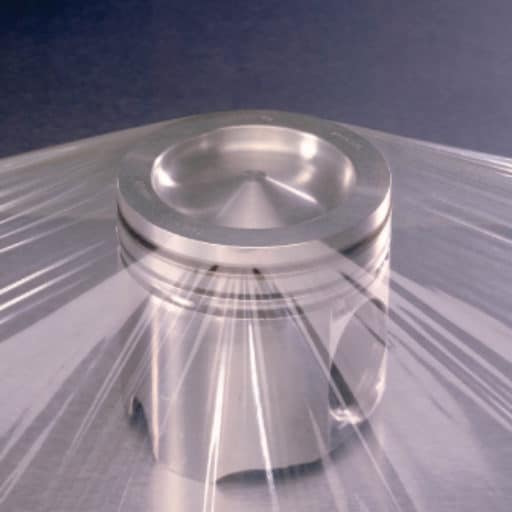

The Best Supplier Award NTN-SNR Pro for our ability to support the implementation of innovative solutions for the protection of precision metal parts.

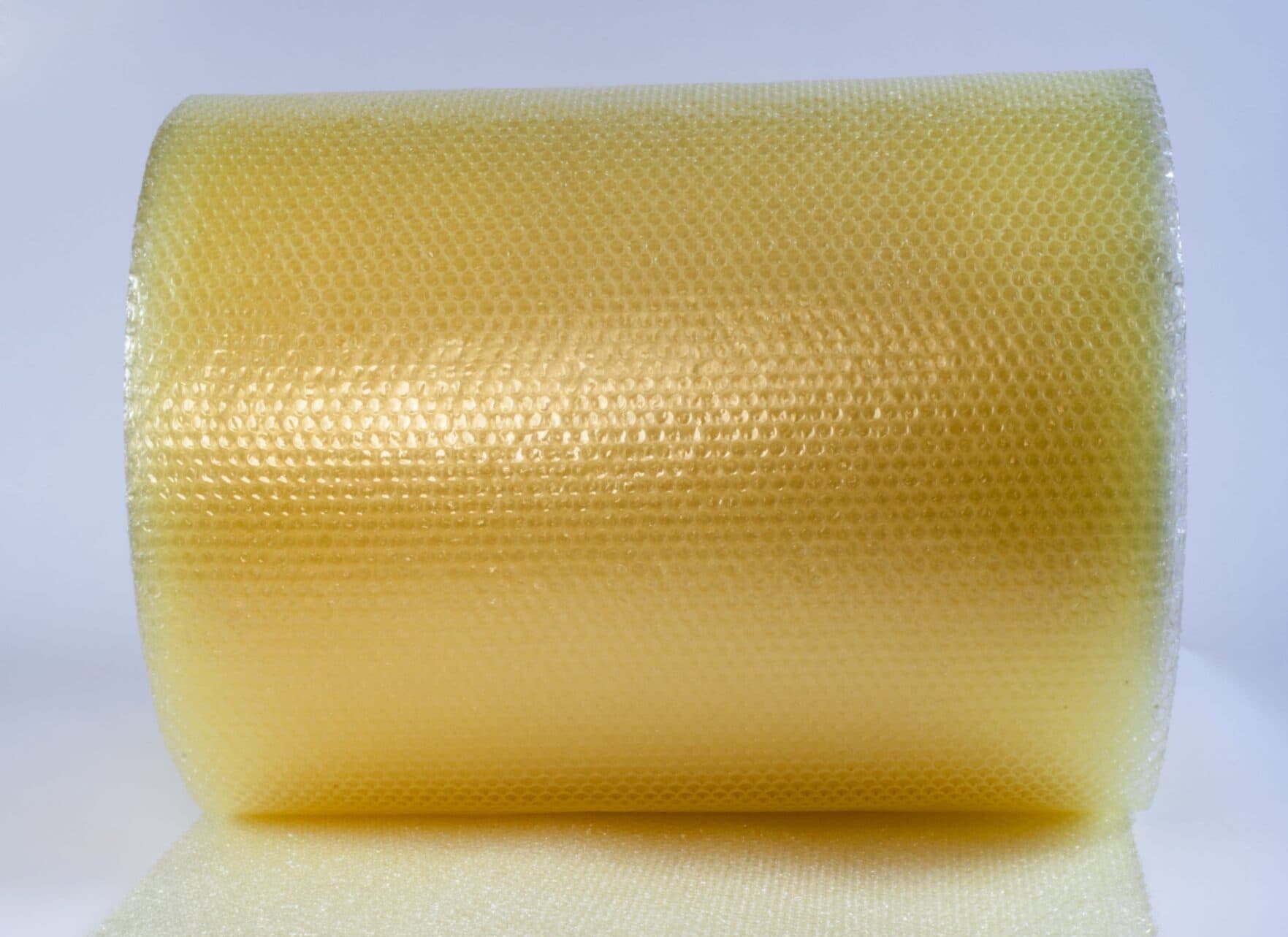

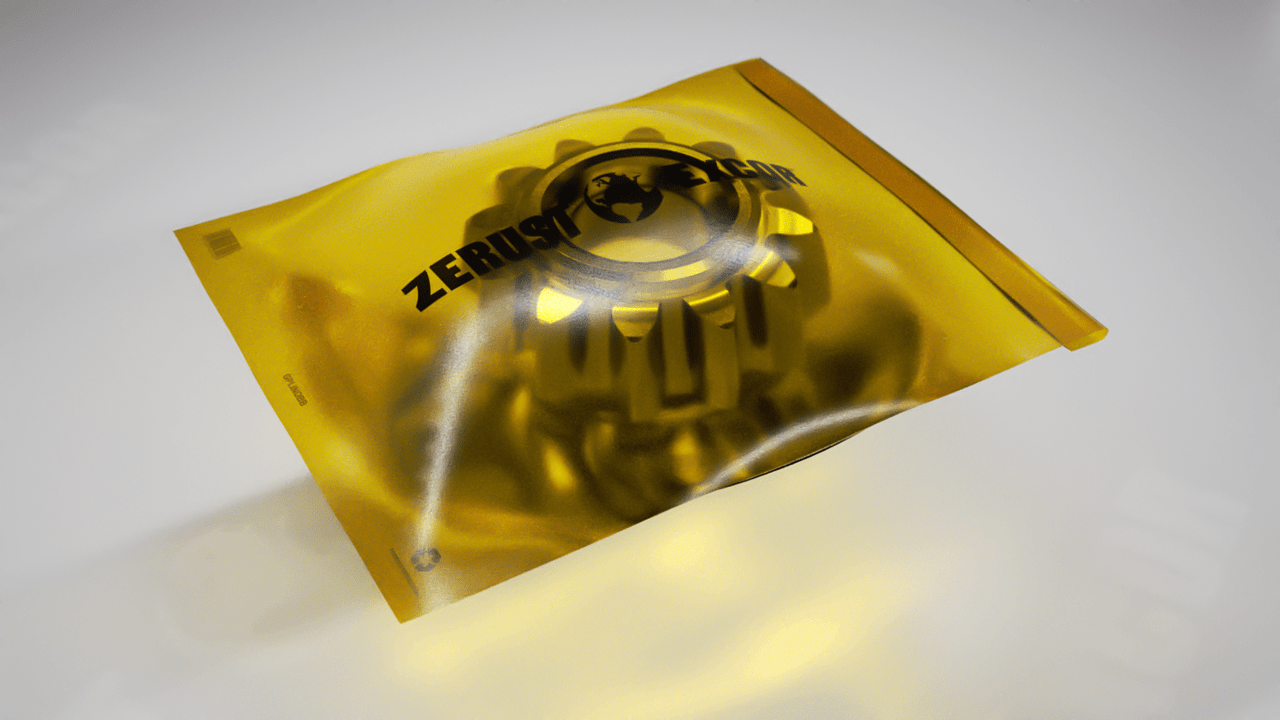

The German packaging award in 2021 for our ICB solution, a new intelligent active principle and a decisive advance in protection against corrosion.