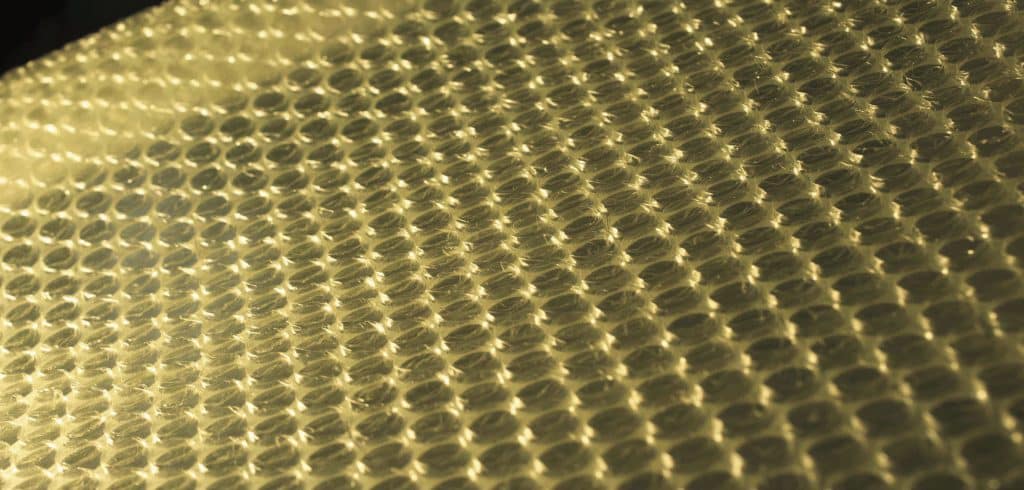

Zerust® Valeno® Bubble film provide protection against corrosion and impact. The Zerust® active anticorrosion molecules are impregnated in the polymer matrix and sublimate from both sides into the atmosphere. This means the user does not have to worry which way a round the product is used. Depending on the design, specific metals and alloys are protected both through direct contact and via the vapor phase within the enclosed packaging. Once the Valeno® Bubble film is opened, the protective molecules evaporate from the metal surface without leaving residue after one to two hours, and the packaged product can be assigned to its intended use without having to undergo any additional processing. Zerust® VCI is an odorless, non-toxic and invisible vapor. Valeno® bubble film comes in a variety of different product variants, such as sheets, flat films, bags, etc.

Main characteristics: Valeno® bubble films are composed of polyethylene and active VCI molecules integrated in the polymer matrix. Active on both sides.

Dosage: One m2 of bubble film can protect up to 10m2 of metal surface. Dosage will vary depending on certain factors (such as packaging design, logistical processes, part pre-treatment, etc.). Therefore, prior technical consultation may be required. Our technical department will be happy to advise you.

Formation of the protective layer: It takes about 2 hours in a hermetically sealed m3 of packaging at 20 °C. The closer the product is to the VCI dispenser, the shorter the protective layer formation time.