An ICB® ("Intelligent Corrosion Blocker") film is a polyethylene plastic film loaded with corrosion inhibitor molecules. It is known that corrosion risk increases at relative humidity levels above 55%. The diffusion of anti-corrosion active ingredients, integrated into the polymer matrix of the ICB® film, increases proportionally to the humidity level. Conversely, it decreases when exposure to humidity decreases again.

Up to 3 years if the application instructions are followed under normal conditions of use, and up to 5 years in a controlled environment (humidity and temperature). In any case, ICB® technology is best suited to long-term protection strategies. In some cases, we can offer up to 15 years of protection.

The saturation time is approximately 1 hour for a hermetically sealed 1 m³ container at 20°C.

ICB® films are non-toxic to the environment and user health, and comply with TRGS 615 and REACH regulations. The independent dermatological institute Dermatest certifies that ICB® film is very well tolerated by the skin.

As with all our products, a Safety Data Sheet is available from our experts.

The main advantage of ICB® lies in its intelligent and adaptive management of corrosion inhibitor release, resulting in more effective, longer-lasting, and potentially safer protection than traditional VCI films.

ICB film is active on both sides and is available with our Slimeline range. This can potentially reduce the amount of packaging material required while extending the shelf life of metal products and thus reducing waste.

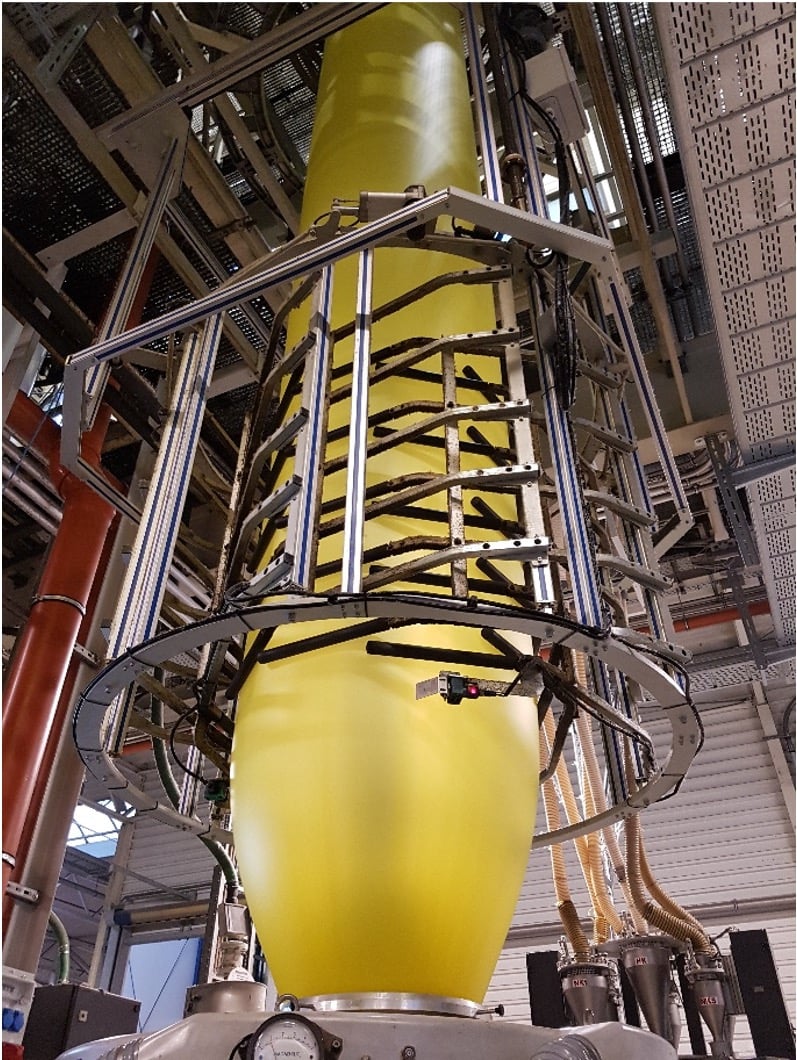

ICB® allows metal parts to be packaged while hot, eliminating the need to wait for parts to cool down.

Once they arrive at their destination, the parts can be unpacked and used immediately without any additional preparation or cleaning steps. The protective layer formed on the surface of the metal disappears in less than an hour without leaving any residue. The anti-corrosion properties comply with level 3 of TL 8135-0043.

ICB® film is transparent, making it convenient for customs inspections.

ICB® film offers adaptive, effective, and clean corrosion protection, while simplifying logistics operations and meeting industrial challenges in terms of performance and sustainability, which earned it an award at the 2025 Global Industrie Awards (France). In addition, it has also won awards...

ICB® stretch film combines corrosion protection ("Intelligent Corrosion Blocker") with the best mechanical performance of industrial stretch film, offering a comprehensive, versatile, and secure solution for packaging metal parts. Our stretch films are available for machine or manual application.